Cleaning and washing liquids

The products are designed for manual application or as refills for various types of industrial washing machines. Liquids are water-based or organic-based. Some water-based products are supplied in the form of concentrate. Each of our liquids contains anti-corrosion additives to guarantee protection against corrosion due to moisture or against oxidation caused by miscellaneous chemical elements contained in the air or direct contact of the part surface with human skin, etc.

The principle of protection is based on the effects of the corrosion inhibitors applied to the part surface or on the passivation reaction of active substances with the part surface. In many cases these two approaches are combined. Solutions can work with ferrous as well as non-ferrous metals.

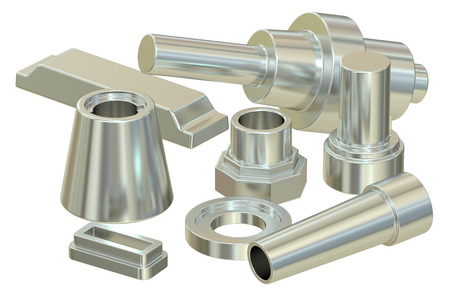

Our products are used mostly in metalworking and automotive industries.

Anticorrosion agents

Corrosion protection products can be divided into two basic groups by type of material to be protected: for ferrous or non-ferrous metals.

These two key groups are divided into subgroups depending on the duration of the provided protection and the method of protection.

Short-term guiding protection is suitable for interim preservation and storage in climate-controlled areas.

Medium-term preservation can be used for storage in buildings without heat control and, in combination with a suitable container, it can also be used for inland transportation.

Products with long-term protective effects have the highest protection factor and as such are used in maritime transport, for outdoor storage under a shelter and for long-term storage that spans several years.

Methods of part protection are classified into oil film or dry film.

The former group offers traditional and reliable corrosion protection and comprises preservative oils.

We offer two types of preservative oils. The difference between them lies in the purpose of use and the provided protective effect.

The latter group - dry preservation - is growing in importance and popularity among users.

Dry preservation ensures reliable protection and, first and foremost, provides an added value because the protected parts are not greasy - there is no oily effect.

This type of protection is particularly useful for corrosion-sensitive surfaces and for parts where an oily/greasy surface is undesirable.

The parts treated with our preservatives often do not have to undergo preservation removal before use.

Our preservatives are used in almost all sectors: inland and maritime transport of individual parts and whole assemblies including automotive, transport of farming machinery, logistical and production processes in metalworking, storage of military materials and weapons.