Multipurpose lubricant

Designed for universal use during production and maintenance. It is a product that guarantees reliable and long-term functionality of individual components or entire systems or serves as an auxiliary consumable for the installation of high-precision mechanical assemblies. Thanks to its chemical properties it can also be used as a product designed to provide supplementary lubrication for light metal-cutting operations, e.g. cutting materials and threading.

The product has a number of integrated functions and allows a broad range of applications:

- reliable lubrication of sliding and rotary surfaces

- operating temperature range from -50 to 250°C

- ability to dissolve and remove carbon deposits and old lubrications, replacing them with its own lubrication component

- because of its low viscosity it rises and effectively penetrates all hard-to-reach areas and joints (can be optionally used as a highly effective anti-seize agent for joints, screws and nuts)

- provides highly effective corrosion protection: where corrosion has already developed and is in its initial stage, the product dissolves and removes it; it stops and contains developed corrosion

- the treated surfaces have excellent hydrophobic properties - repelling water and moisture, and are protected against the effects of salts

Application of the product: lubrication of individual parts for easy assembly, protection of joints against corrosion, lubrication of sliding and rotary surfaces of handling and production equipment, supplementary lubrication for metal-cutting operations, preservative...

Special lubricants

Lubrication production designed for a specific purpose of use. The lubricants have been developed for reliable lubrication, protection and proper mechanical function of individual components and complete assemblies.

We use the technology of self-drying lubricants which allows the product to dry after application. While at rest, it is solid, almost non-greasy, but as soon as it is exposed to pressure or friction, its lubrication components are liquefied and the specific surface parts can slide or rotate easily with minimum frictional resistance. Thanks to this design the created microfilm limits the capture of dust and other contaminants and repels water. The products also contain corrosion inhibitors which provide very effective protection against corrosion. In addition, the products have a cleaning ability to partly remove older lubricants and ordinary operating deposits, so they can be used as cleaners during servicing.

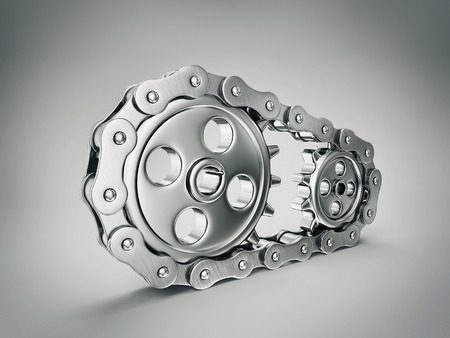

Potential application: lubrication of mechanical parts of handling and production equipment such as link chains, sliding rails, articulated joints, simple gear boxes, pulleys, rope mechanisms, doors, gates, guides, etc.